NAME: Schöneberger Hocker

WHAT: Product

MADE FOR: SELF

English & Deutsch

–

Schöneberg Open Stool

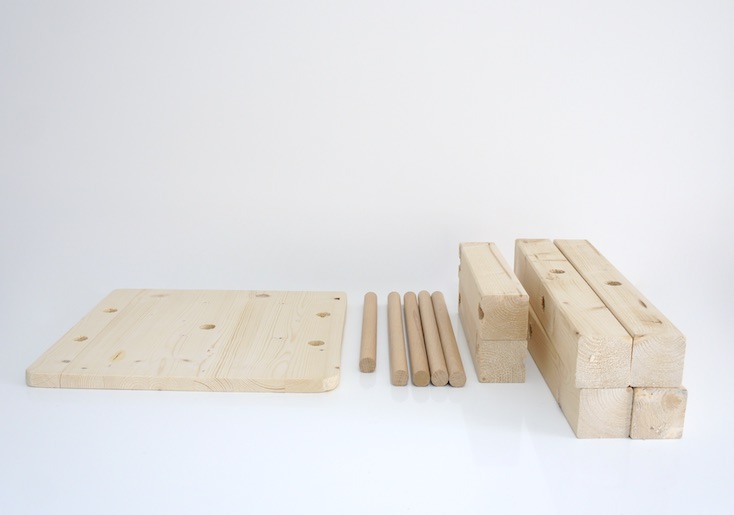

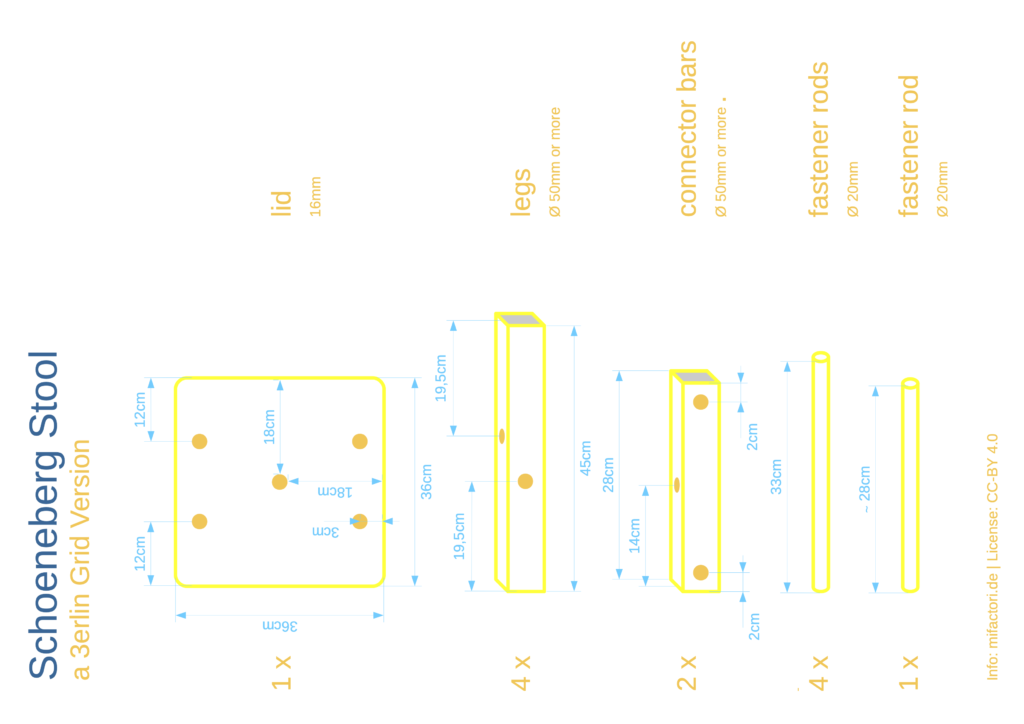

The Schöneberg Stool is an open circular design by Mifactori. It is a simple solution to make a modular stool without external fasteners from all kinds of materials with only beginners level craftsmanship skills.

Content

1 How it works ↓, 2 Variations ↓, 3 Sustainability Discussion ↓, 4 Credits ↓, 5 Conclusion ↓

–

1 How it works

Parts ↑, Assembly ↓

Just assemble it from finished parts without any external fasteners. The construction stabilizes/blocks itself. It can’t fall apart.

The core solution works with different materials ↓ and requires just absolute basic craftsmanship if angular beams are used. An efficient industrial production from upcycled beams and bars is possible.

Making/manufacturing the parts is incredibly easy:

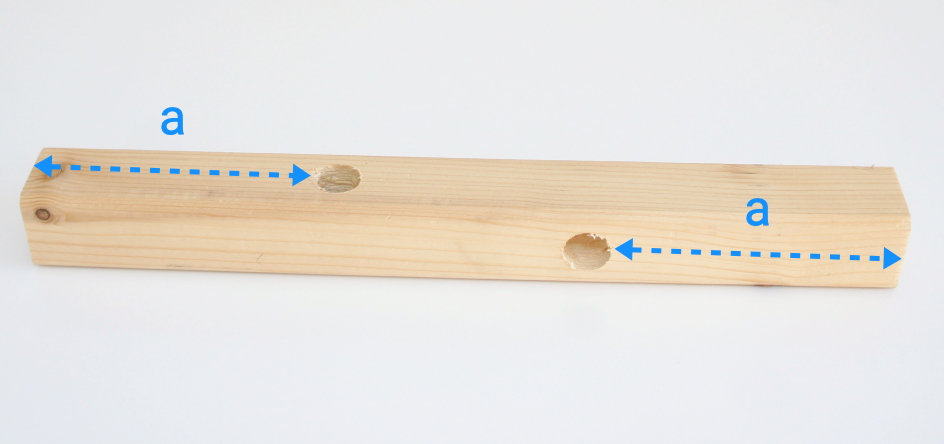

Ensure the holes in the legs have the same distance to bottom and top, just use a side stop on your drill press. The exact distance doesn’t matter. Our versions follow the 3erlin Grid of course, yours doesn’t have to.

Drill the center hole of one connecting rod completely through and the other only to three quarters.

All holes don’t need to be super correct on the X axis, it’ll aways work. But you need to make sure they are on the same spot on the Y axis in the connector rods.

Make sure sure the diameter of the lid is big enough so it can’t fall of when spinning.

Obviously the holes you drill need to be the same diameter as the bars you put through them. We found that 16mm beech is strong enough for smaller stools. For larger ones go to 20mm.

As you might have guessed. The stool is a bit dynamic. But other stools are too. You can trust it 100%.

That’s it. That is the core. Now let’s play with it.

–

2 Variations, Forks, Hacks

As usual with Open Circular Design there are a lot of versions and → forks possible. The Schoeneberg Stool uses a construction technique that can be transformed and adapted in many ways.

.

Rope goes very well with this design. The lid in the version we provide measures for already has extra holes. Rope can prevent the lid from spinning or falling off. There are many different ways to use the rope, have fun to come up with our own no matter if you use rope clamps or knots.

.

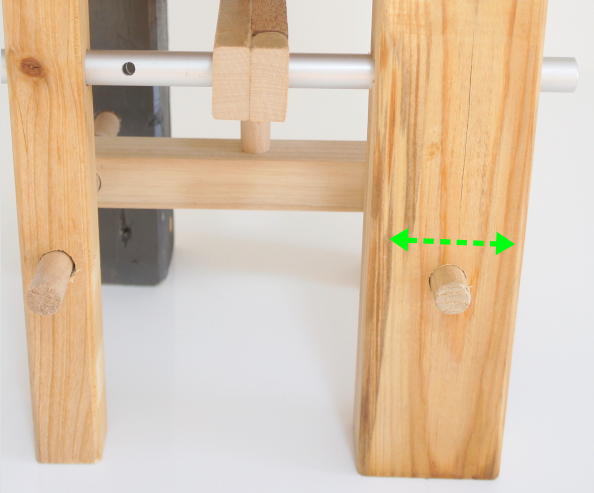

Rubber bands help when sliding out beams are seen as a problem. Silicone (1) is long lasting and recyclable, sealing rings (2) work well too and bike tires are a free source for your own upcycled and pretty long lasting ones!

.

Another way to deal with sliding out poles is a bit more invasive to the material: Small holes on one side or both sides of the rods open up possibilities for bolts, strings or key rings (1). You can combine this with the rope technique above and make a “rope in one” from leg to lid to leg.

And just a fun one. We found a lid from an old prototype with a larger hole that already inspired → Ringbein. We also had wooden ball in our scrap wood pile. Together they made a nice remix of the design.

.

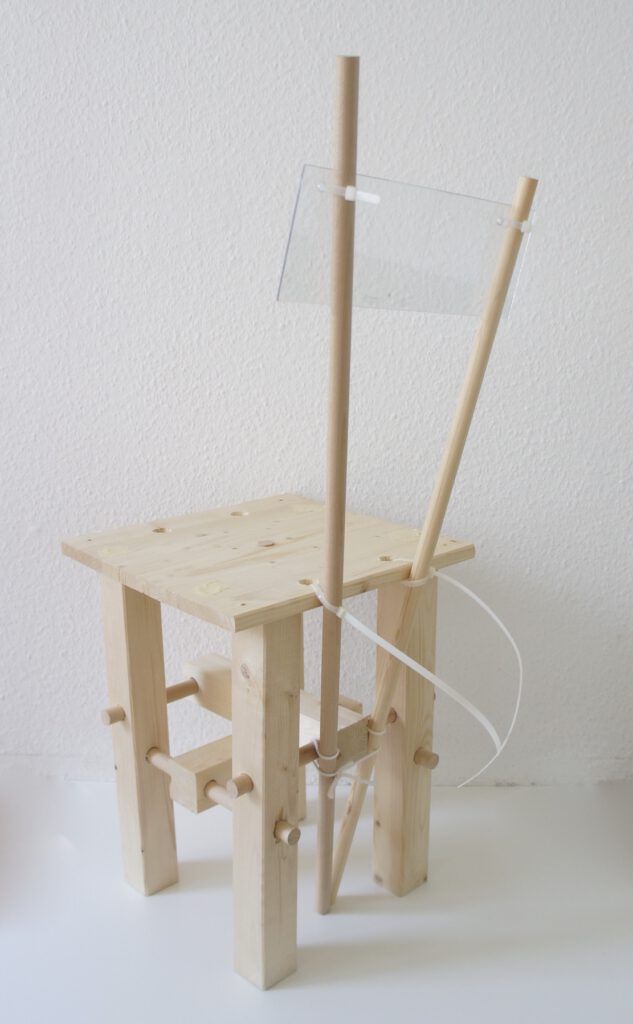

Within seconds the stool can be transformed into a full chair. It is surprisingly comfortable to sit on. Here is one way to make it ↓

7

.

Just add two poles (Ø 20mm) and a backrest board.

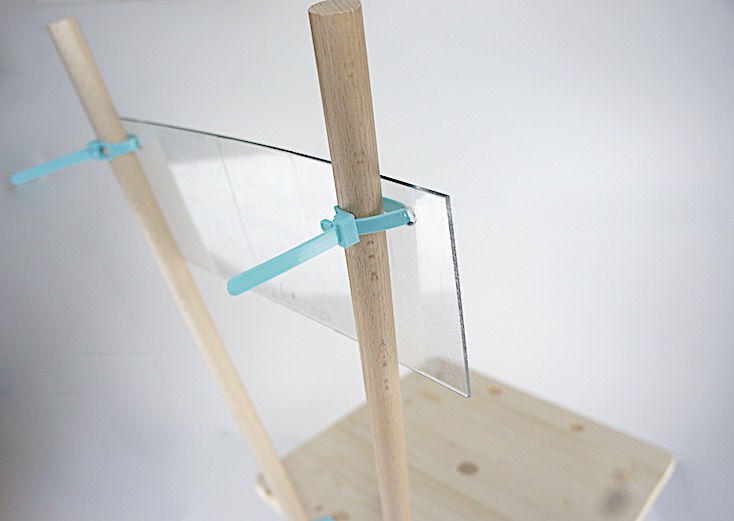

All connections are made with reusable tie binders (1). (Img 1, 2, 5)

Fasten the poles on the outside of the lid to get an angle in the backrest. (Img 1, 6)

Fasten the backrest board also with reusable tie binders. It works because the poles of the backrest are tapered towards the bottom – the back is shaped like a “V”. Therefore the backrest board cannot slide down. (Img 5)

Chose a strong but bendable material for your backrest board. This makes this pop up chair more comfortable. (Img 3)

Use the provided 3erlin Grid measures to get a well working size of your stool and chair. (Img 7)

The chair in the pictures above is stable, comfortable and pretty safe. However In most chairs the back leg is behind the highest point of the backrest for safety reasons (Img 6). So this is an Open End for you to solve.

The whole stool (and chair) is transformable. We made different versions of the stool and reused the parts in other designs already (example 1, more to come). Come up with your remix or further development. Send us pictures if you like.

*

3 Sustainability Discussion

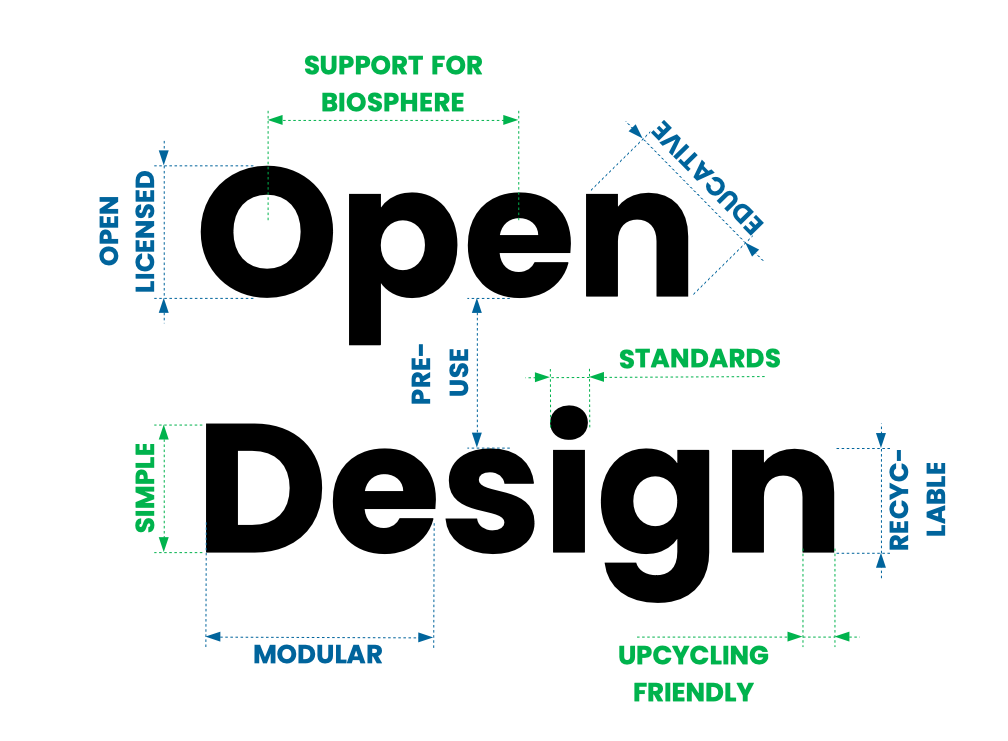

This works well as open circular design, it checks most boxes of the methodologies.

Simple → Once you’ve understood it everything is pretty simple to assemble and manufacture. Beginners level woodworking skills and a saw and drill (preferably a chop saw and drill press) for tools is enough .

Standards → You can use all kinds of wood or materials with this design especially standard parts like angular beams and round bars.

Recyclable → All examples above are made from well recyclable materials. This design supports recyclability. It doesn’t need material mixes and can be disassembled within seconds.

Upcycling friendly → Perfect to give old parts and used materials a new live – probably even through efficient mass production. Even round bars are quite easy to source through upcycling for example from old children beds, broken camping chairs, clothes dryers and so on.

Biosphere Support → No direct support for plants and animals. Add one : – )

Educative → The simple but interesting construction technique opens new perspectives on connecting things and reusing existing materials.

Open Licenses → As always and just in case our open licenses apply. But the key to this design is how it works technically and technical solutions are subject to patent law or design rights which both require novelty and it is absolutely unlikely that this technical solution is novel. So go for it. You look at free hardware.

Pre-Use → Cutting and drilling is involved but not in a way that undermines the potential of these bars, rods and lids to be used for many different things afterwards. (What is “Pre-Use”?)

*

4 Credits

As said under Open Licenses above this design is basically just a technical solution that is around for centuries. We (re)discovered it ourselves though and a quick search didn’t bring up other example uses. We were just to lazy to search longer. If you happen to know some pls. send us a message, we are happy to add it here as inspiration for us and others.

5 Conclusion

Because this design is so easy to source and produce and because its parts are modular and reusable (as we will show in future postings) we give this Open Circular Design 5 out of 5 stars.

★★★★★

.

Criticism: It is unclear how this design performs in long term use. There is relatively much play between the parts. It seems not unlikely that with heavy use the construction will quickly become more and more unstable. Glue can solve this problem. But with glue modularity goes down a bit.

Support us → We would really love to see a version made from high quality dark hardwood with high level craftsmanship. Pictures or wood donations welcome. Send us an email.

–

More:

- Full Flickr album for Schöneberger Steckhocker

- Study more of our Open Circular Designs → here. (More like this to come.)

- Don‘t want to miss future updates? Sign Up to our Newsletter or follow us on one of our Social Media Channels →

*

Deutsche Version

Es gibt für die wenigen Texte hier leider keine deutsche Version von uns. Aber Chrome und Firefox erlauben die automatische Übersetzung jeder Seite – die Seite wird dann einfach auf Deutsch angezeigt. Dazu einfach Mausklick links auf die Seite → “Übersetzen in” → fertig. (So geht’s)