Title: What is the final version in Open Circular Design?

What: Article

Ordered by: SELF

.

English & Deutsch ↓

The Mifactori Open Design Lamp Or

What Is The Final Version In Open Circular Design?

When we started to develop an open circular lamp a couple of years ago we always thought that we’d end up with one final nice version of a lamp. But this turned out to be impossible but also unnecessary and even undesireable. Here is why:

The goal was a lamp that is open and circular. We wanted a lamp that is easy to make from standard parts available in every regular hardware store. All parts needed to be modular and the design would keep them fit for reuse – no glues, no cuts, no paints.

But this kind of modularity made it so hard to come up with one final design. There are just many parts on store shelves that work in a lamp. We went through many iterations and remixes of lamps that were all equally good and (re)used the same parts. And with every new version we felt that we moved away from a final design instead of getting closer to it. Till we finally understood what was happening and switched gears.

.

Final is finite, circularity is not

.

Let’s start with this question: Why have we been under the impression that we need one final design?

I think this is what we used to in todays world. In fact, every industrial designer basically is in a similar situation at the beginning of a design process. There are almost infinite possibilities for parts, materials, colours, shapes, production and construction techniques, many of them work in a lamp. But at some point final decisions need to be made. The reason for this is usually mass production. Factories in the past and still today have a hard time to produce different versions of something and keeping the price low at the same time. So you need one final design to adjust the mass production process to. And the cost per copy falls. This is industrial design.

But with our approach to an open circular lamp the situation is different. The lamp is made for flexible distributed manufacturing. It uses readily (and locally) available standard parts and materials. These parts and materials come from already existing mass production. You don’t need to set up a specific production line for the lamp. With this there is no need from the production side for one final design.

But what happens if you want to sell lamps? You still have the packaging, shipping and marketing problem left. Do they need a final design?

*

*

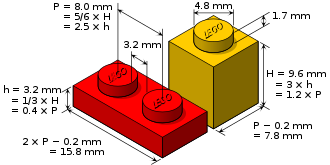

This can be compared with modular building bricks like the ones from LEGO, Cada, Cobi, Qman and so on. How many different standard parts (bricks) are there? A lot. These bricks are mass manufactured. And like with our lamps, there is an infinite number of models you can make with them. But the models don’t effect the design of the production process of the bricks.

How do these companies bring the bricks to the market? How do they tackle packaging, shipping and marketing? With sets. You buy a bunch of bricks that usually come with free instructions on how to turn this specific selection into something – a plane, a spaceship, a house etc. But you can reuse the bricks for your own designs or find alternative models for a given selection on all kinds of platforms.

What do we learn from this for our Open Design Lamp and for Open Circular Design overall? A lot! It raises many questions. We don’t have the answers to all them (yet). Here are just some insights so far:

→

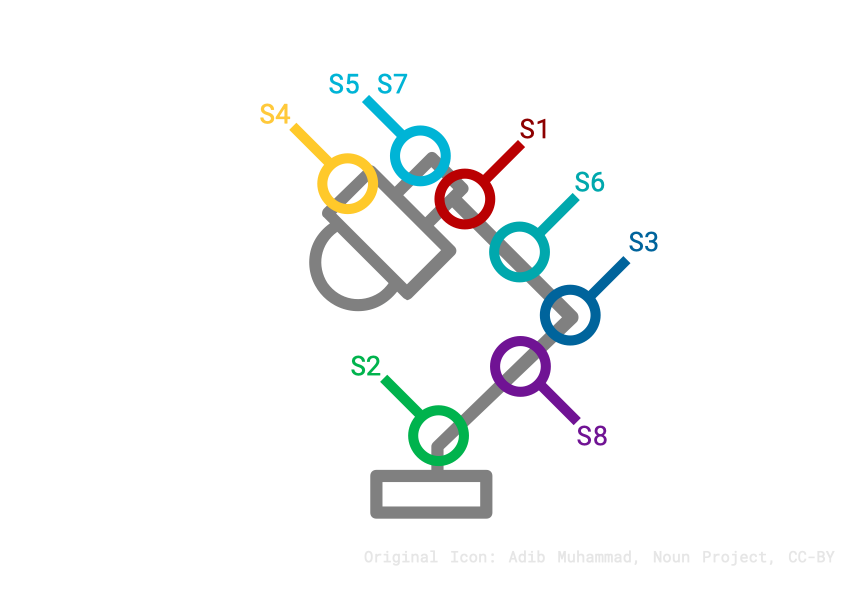

1 Documentation For Reoccurring Joints & Solutions

→

When you make a lamp, you‘ll encounter a bunch of reoccurring problems. For example, how to fix the socket to the rest of your lamp. You‘ll find solutions for this problem as we did this using only readily available standard parts. Good solutions tend to be reused – in different versions though, but with the same core finding/idea. They become somewhat fix. These solutions are the lamp! An open circular lamp is a collection of solutions on how to assemble a lamp from standard parts. So these solutions need to be documented. And this is what we did! Check: → The Mifactori Open Design Lamp – Solutions & Joints

*

2 Final Is Finite Is The Enemy Of Circularity?

→

This is more a question.

Circular design is about enabling reuse of parts. This would mean that there are lot of parts from different manufacturers flying around for reuse. So circular designs would probably integrate those parts. This means the more flexible a circular design is (the more parts it can use) the more circular it is. To have one final design that needs a very specific production process and selection of parts would basically undermine its circularity. Because it can get hard to get these parts.

So a good circular design is fit for distributed manufacturing. Having very specific requests on parts, materials and processes won’t make it easier to produce a design on site. A good open and distributed design supports you in sourcing parts and materials? And the key to this is that it just does NOT have a final design? (More on this here).

*

A circular and distributed design supports you in sourcing parts and materials. The key to this is not to have ONE narrow final design?

*

What is the final version of raised beds from euro pallets?

There is none. Right. #open #circularity

— Mifactori Studio (@mifactori) May 6, 2021

→

3 A Database Of Parts?

→

Looking at Lego again, you might get the idea for a database of all parts ever used in a lamp. Every Lego brick has a unique number. This enables many interesting things. To name just one: The users of the platform Rebrickable can create a list of all Lego sets they own. For each Lego set there is a list of parts that are included in it. So the platform knows all the Lego parts a user owns. And from this, it suggests other models they can make with the parts they already have. This would be great for circularity especially the for the reuse side of it. Organise remix and reuse with a smart database.

But Lego is just one company with a finite number of bricks and consistent numbers for these bricks. If you make an open circular design like my lamps, you‘ll use parts of many different companies. And Open Circular Design enables you often to include also old recovered parts and materials, scraps and local things into the design. A finite number of parts and consistent numbering of them is therefore a complex challenge.

Maybe one solution here is to define the system not as its parts but as the combination techniques (solutions) it uses – like we did with our lamp solution & joints post. But when you grow this, it will bring a certain level of abstraction a lot of people won‘t be willing or able to handle. This which limits the openness of the system. Everyone can follow the simple brick by brick instructions by Lego. But instructions based on combinations is a very niche nerdy thingy most people don‘t get*.

Another solution idea could be to give the system a name (for example “Baubus”) and every design that was ever labeled under “Baubus” adds its part to the list. Like a company name, a lead brand. The list grows. Popular parts reappear and are emphasized. Lego has many competitors. Some of them invent new compatible parts. These new parts don‘t have official Lego numbers and therefore can’t be processed by platforms like Rebrickable. Exact copies can/could?

I leave this unsolved for today. What is your idea? How to organise a connection between the parts that supports their circular reuse and recombination? Using digital tools?

→

4 The Marketing Problem: Not „One Job“

→

As said above, if you want to sell lamps you’ll still have the packaging, shipping and marketing problem left.

And here you get a problem if you have many equal versions of a product coming out of „the production process“. For example when taking pictures. If it takes one hour to take pictures of one lamp, but to do this for eleven takes a full working day! And taking pictures is just one of many many steps in marketing.

.

.

How to spread it? How to spread the message? If you have just one product you use just one image and just one documentation to communicate across the globe. How does this look for a fertile growing throng of iterations?

Marketing is always a big challenge. The problems just mentioned show that the traditional approach to marketing does not work that well with the kind of open circular design we are exploring here. Different strategies need to be found and built. We are looking forward to do this in the coming years. Together with you. Let us know your ideas.

Update/Small Addition: A great thing about this modular and circular approach to the design is that assembly instructions are quick and cheap to make. If you build something where you cut down, drill or paint materials, you have to build your prototype first and then, for your video, built a second version starting from scratch. Our lamps are easy to disassemble. So the documentation is just a video where you take the object apart and then play the video backwards. Something we‘ll do a lot more in the future. (See also: Innovation Costs In An Open Circular World)

→

5 Business Model

→

How to earn money with this kind of design? I will not go here into an extended lesson on business models for open things because I did this already in other posts (1 | 2). So, I‘ll just tell you what our business model is, right now, for the designs we created:

I. Affiliate links: In the documentation of the lamps and solutions you‘ll find parts lists that consist of links to Amazon. These are affiliate links. When people enter Amazon through these links and buy something we get a small part of the money exchanged without the purchase becoming more expensive for you. This is just a start. There are more companies that offer affiliate link opportunities. And when all of this works well other deals with even more companies might become interesting. They have the shops, the parts and the shipping. We just show use cases for the parts/create the need. We are advertisers. | Update → didn’t work for us, not enough outreach

II. Prototypes on Ebay: We created all these prototypes which was fun. But now, we don‘t need them here anymore. We can disassemble them and get the parts back for future projects. But we‘ll try something else first: Sell them. We will not set up our own shop for this, but use Ebay instead. People know and trust Ebay already and the purchases are insured. Very quick. | Update → didn’t work for us so far

III. Advertisement for our work: But the lamps and publication of them are advertisement for our design work and the approach we use. We like to get hired for custom jobs. We like to develop more products like this or exhibition designs and so on. This is what we love to do and are interested in. Developing new things rather than dealing with packaging, shipping and marketing of existing things.

IV. Lecturing: Posting these designs alongside texts with theoretical insights like the one you are looking at right now clearly indicates our interest in researching and communicating knowledge. We like to give talks and lectures and we are good at it. And it works. We get hired to do this every now and then which contributes to our income.

There are more possibilities we might use in the future. We‘ll update the list above when they are no longer just theoretical.

But the message is: We are talking about a diverse mix of income streams. Something you‘ll find quite often with companies developing open source products.

→

6 Openness To Trust: Be Boring ?

→

But how to make a really open system? Openness has many sides and one of it is about legal things. Especially with the design of objects you run into the problem of „design rights“ which will always pose a risk for others that want to copy you. There is no good way right now to communicate legally binding to others that you will not make use of your unregistered design rights. At Mifactori we explore our own way of taking care of this. But here is another idea or question:

Design rights usually require that you do something that is unique, new or special. Try to avoid this. Make something that is not unique enough for design rights (or even patents)? Made just with well established boring prior art… This can create legal security for others. Remix existing free culture in a way that it keeps it remixable.

I think this is an interesting question. Does Sustainability need to look „boring“? Hack the system of intellectual property rights. It works against sustainability (because it always is about blocking others to do something with your creations while sustainable circularity is foremost about enabling others for this – enabling them to repair, reuse, refurbish and recycle). Hack it with being boring. Make unprotectable things.

Is this possible?

🙂 Let’s try. Harder! Stay informed about our progress. Sign up to our Newsletter.

. .^. .

°(◠‿◕)°

–

Deutsche Version

Eine deutsche Version gibt es noch nicht, leider. Bis dahin einfach DeepL benutzen oder den Artikel direkt im Browser mit einem Klick auf Deutsch übersetzen.

–

* The links to Amazon are affiliate links. The offers behind them are not from us. Through the link we receive a commission if a purchase is made without making it more expensive for you. If you buy through Amazon and go through the link, that helps. Thanks.

Image Credits (for images not by us): Lego Dimensions.SVG, by Cmglee (Wikimedia Commons), CC-BY-SA