2019

Title: Rectangalize It!

What: Article

Made For: Theory

–

Rectangalize It!

Turn scraps from digital production into multi-use modular parts using automation.

° ° ° °

A couple of months ago I was in Copenhagen at an event by the Danish Design Center using the opportunity to visit a local company called Stykka.

Stykka offers surprinsingly cheap custom made furniture. The cheap prize and customisation is possible because of their digital fabrication friendly designs and highly automated processes.

All furniture is made from sheet material like plywood or acrylic glass (plexiglass) and they have CNC machines and laser cutters in their factory. As a customer you can visit them and design your furniture if you like using a virtual reality environment. Once you are happy with your design Stykka hits the Return button and the machines next door start the production. The translation from your plans – the graphics you see on your screen or in your VR-Goggles – to the factory in the next room happens automated. No designer, no engineer, no factory worker is needed in between (almost). This is the magic of digital fabrication and one of the reasons Stykka can offer affordable solutions.

sheet material left overs

.

As a circularity designer I was of course interested in what happens to the scraps – the leftover material. Our host from Stykka showed us the garbage bins. I took the pictures above. They told us that they have this amount pretty often. We joked if I can come up with a use case for this garbage, I am welcome to share it. On my way home I did have an idea. And here it is:

–

Rectangalize It ☐ ☐ ☐ ☐

Automate rectangles in.

Or automate something in.

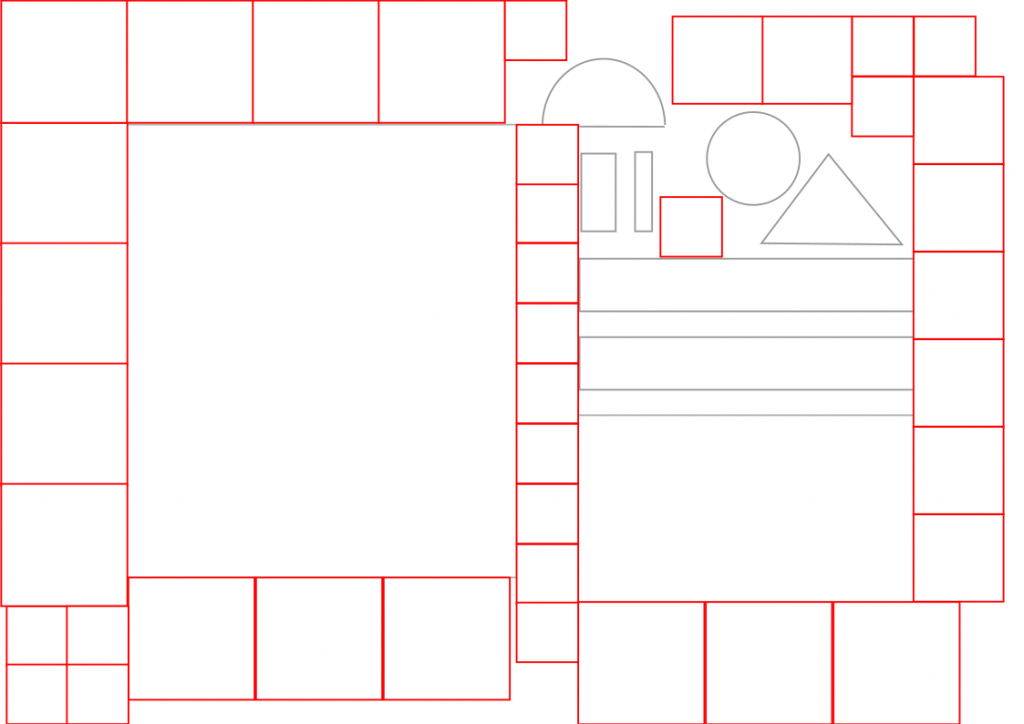

The idea is simple: When you have an automated process anyway you can also automatically fill in all the unused space in your materials with other things. Fill in the blanks.

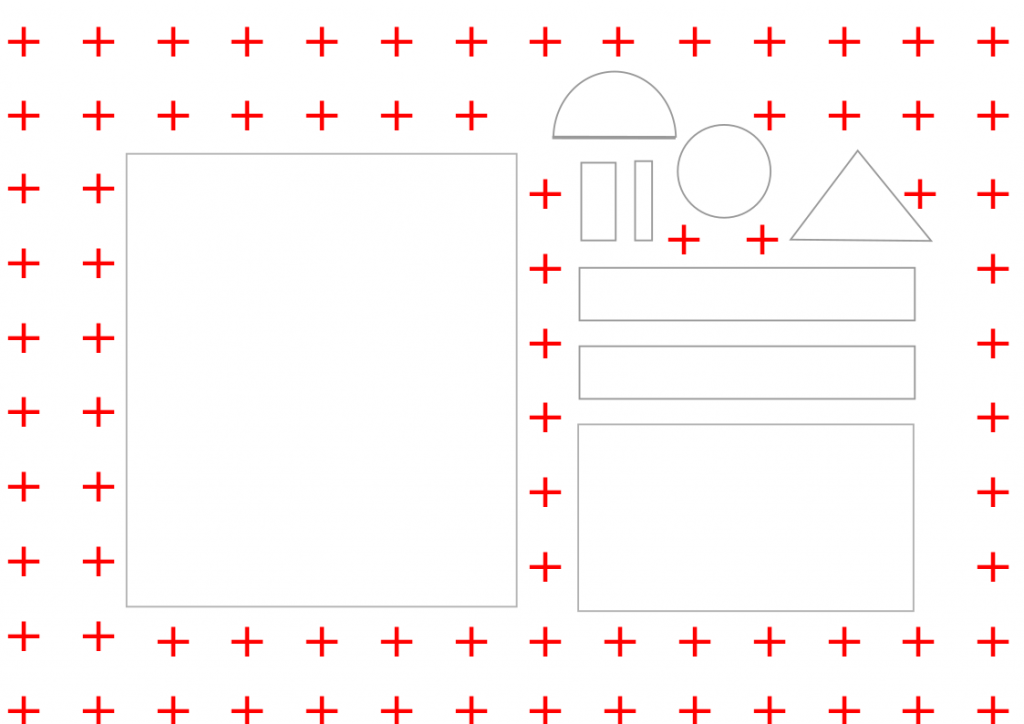

your furniture

use the free space through automation

.

This is easy. The more difficult question is, what could this be?

The difficulty is not so much to add something but to make something where there is a need for it or where a need could be created. It should be possible to market it.

Here are a few first ideas.

–

#Modular Parts | 3erlin Grid

Well of course my first idea is to fill in the blanks with multi-use modular parts. Multi-use might result into creating more than just one market opportunity at the same time.

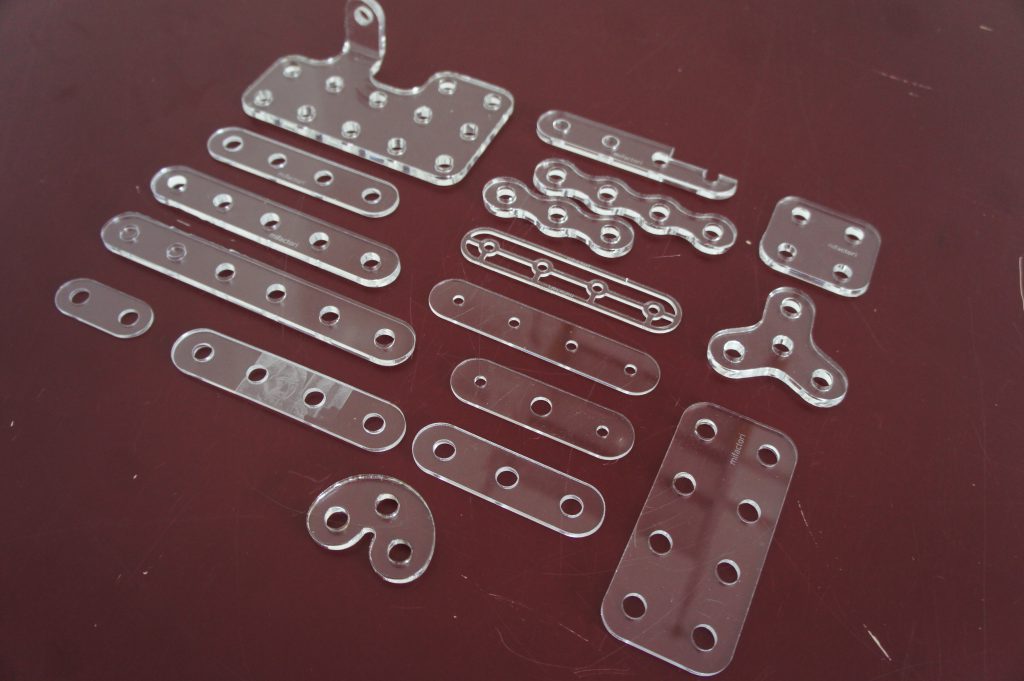

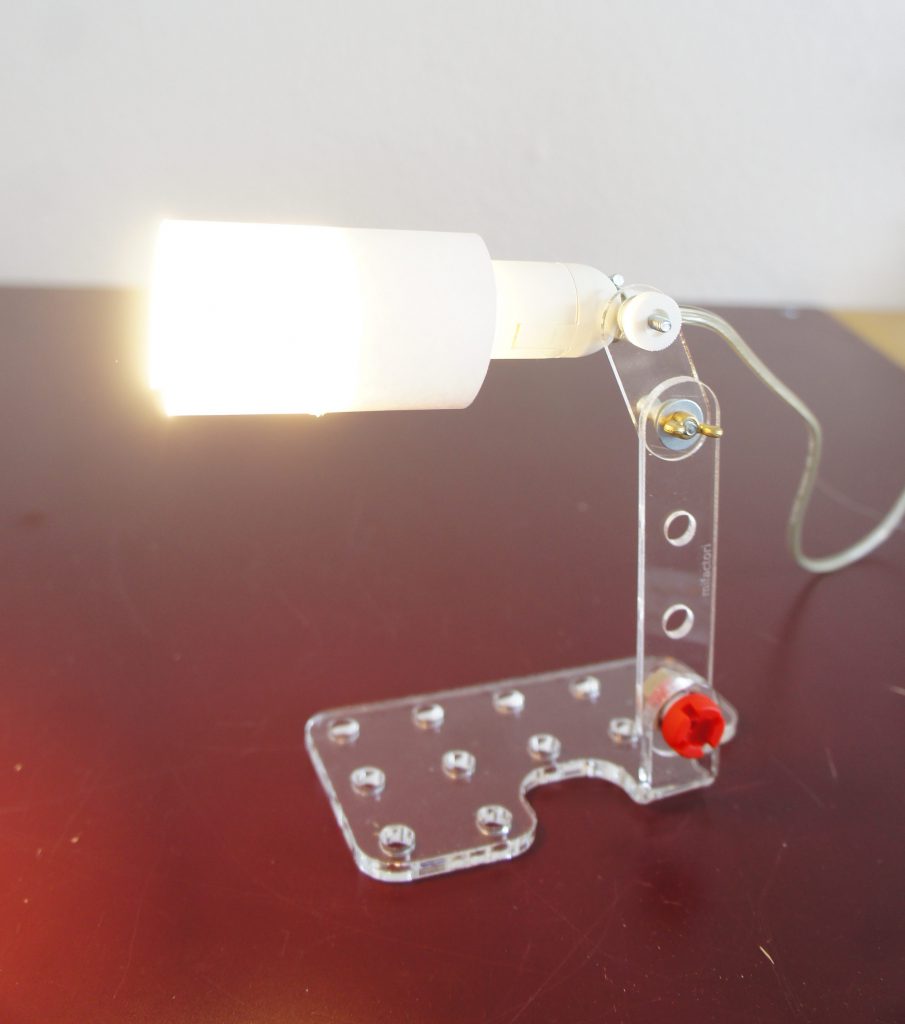

My personal first go to are Heros-Parts or 3erlin Grid Parts – so parts like Meccano or Open Structures.

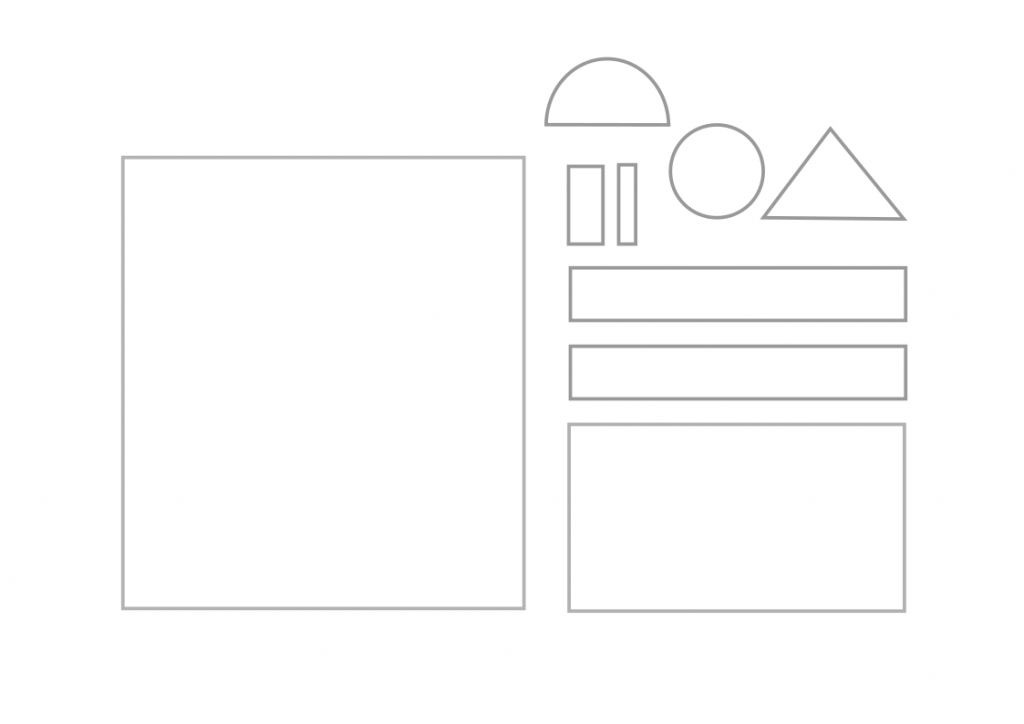

automate grid parts into the vector file

.

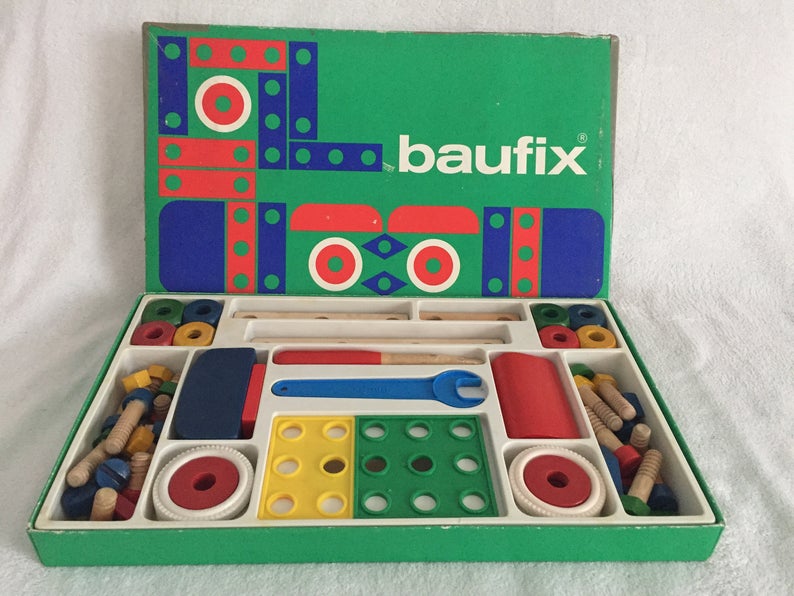

There are many things you can build with parts like these as toys like Baufix and Meccano and real world design concepts like Open Structures and Grid Beam show us.

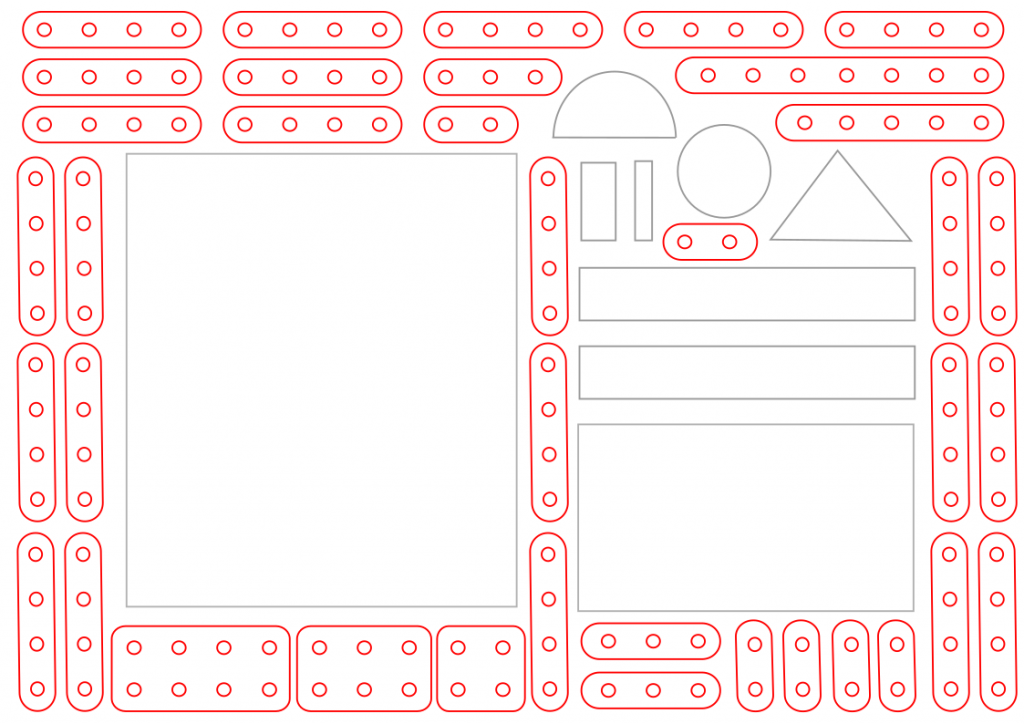

I made myself from leftover materials at the digital fabrication center at the HBKsaar university where I worked as a guest professor in design for one semester some 3erlin Grid parts and started prototyping lamps with them.

more pictures from the lamp prototyping are shared here

experimenting shapes & angles; more pics here; Download vector files

prototypes for new hypercircularity lamps, see older ones here

.

The interesting thing is that Stykka also sells lamps wich is not very surprising when you think about it – desks often go with lamps.

So why not make lamps like this or similar ones automatically cut out of the scraps in your materials.

Well and lamps are just one thing. Just start searching for Meccano parts and instructions or something similar to start a journey into inspiration for other things.

meccano collection in pinterest

.

And there you have your next idea right away. Pack them together, combine them with some regular nuts and bolts and offer them to kids or schools as building toys.

source: Wikimedia Commons, CC-BY-SA 4.0, by: Stadlbauer

.

These parts fit together because of the same connection standard (grid and fastener). But with this you can go even one level deeper. And think about to:

–

Rectangalize It \☐/ !

Rectangles are a very basic universal shapes. Cut them out in different sizes, pack them and sell them.

different standard rectangle sizes automatically added in

.

You can do a lot with rectangles. They are basically the sheet material for smaller objects.

One of my next stops in Copenhagen after Stykka was the Museum „Ny Carlsberg Glyptotek“ where I saw this art work made from small transparent rectangles:

A big wall from rectangle tiles

.

Going back to the school idea from above you can sell it in packages as craft materials.

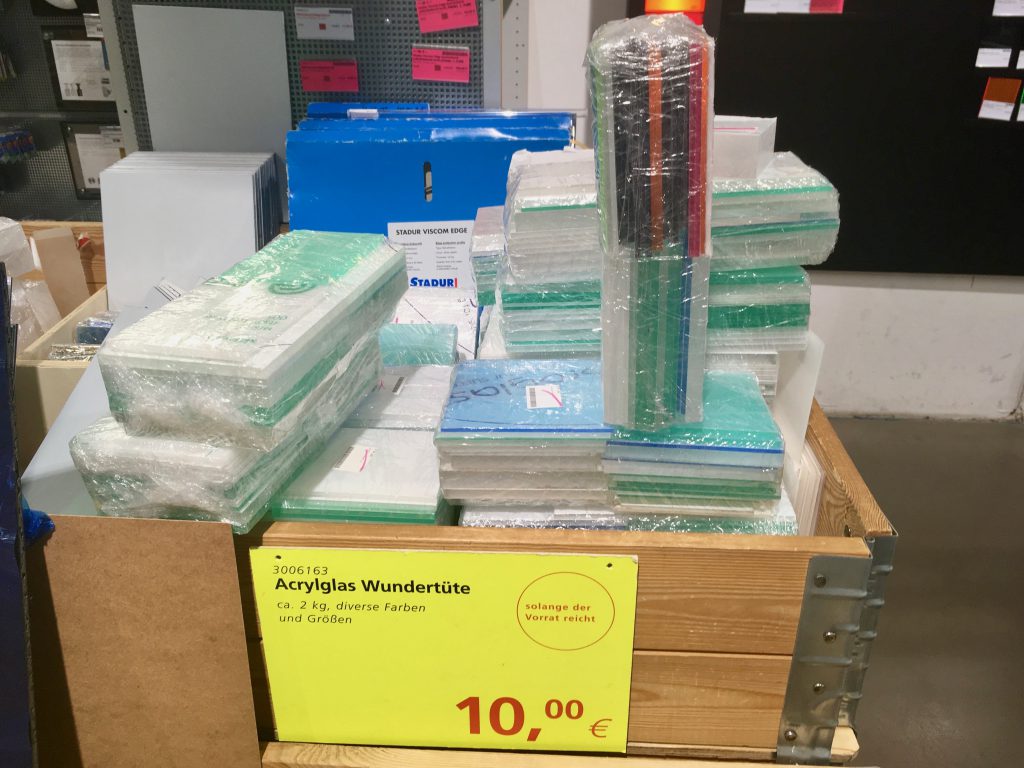

Modulor in Berlin sells big packs of small plexiglass rectangles as „Acrylgals Wundertüte“ (surprise bags) in their store to creative people and I am sure the source for these rectangles is the same that I am suggesting here right now.

Acrylglas Wundertüte @Modulor, used by us for example in the PET-Palace

.

Probably a lot of designs can be found to work with rectangles (or modular parts like Meccano and so on). And the more of these designs are around the bigger the market for the rectangles.

–

#Openness As A Driver

Well, and here could Openness help a lot. If these design ideas are open, many companies or general people could use them and therefore grow the market for these “rectangles” or “modular parts” quickly. And open designs could help to get others in to create even more open designs and …

Well. As designers for sustainable circularity and openness let‘s all work more with rectangles or universal modular parts from sheet material. It seems to be a good idea, anyway, always.