noTALKI

noTALKI is a stool with character, created for the open circular design project Ikego.World. It reuses parts that were developed for chair series “WORMS” to create a friendly little buddy that helps you to grow and/or maybe feel less alone sometimes.

There are two versions. One uses as board the existing Marii Board (number). But we also added a new board and a 60mm spacer. New parts see below.

Version 1 (new board)

Version 2 (with Marii Board)

In Action

↑ Because the Marii board has extra holes, you can play with additional Ikego parts and grow your character.

…

Ikego

1 General info

Parts

- 082.1 M6 bolt 50mm

- 082.4 M6 bolt 110mm

- 094.1 M6 threaded rod 50mm

- 110.1 Marii Board

- + 5 new parts, see below

IP protected?

No, and not planned!

Professional local makes:

Are allowed. If you like, please donate 1 Euro per make to: paypalme/lars2i

–

2 New parts

(As mentioned above, these parts were developed for “WORMS” and reused here. But noTALKI was released first, so we document these parts here.)

1

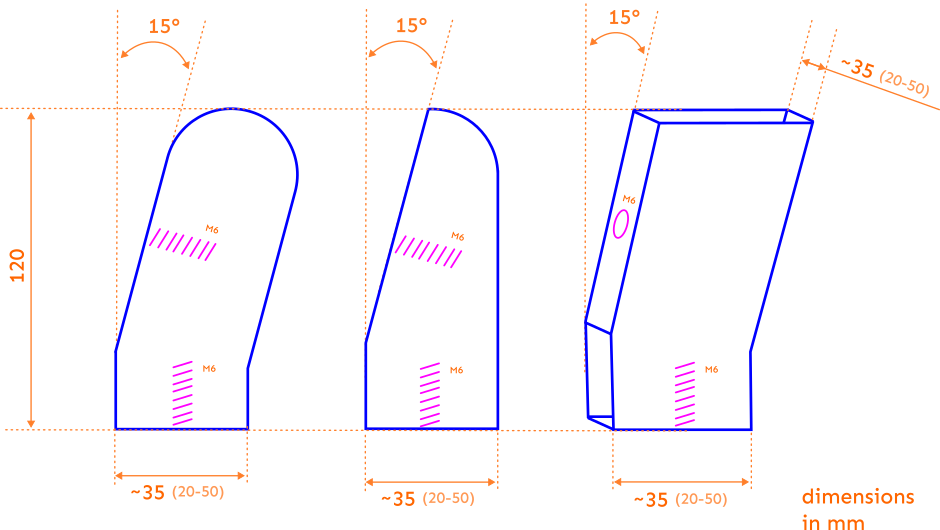

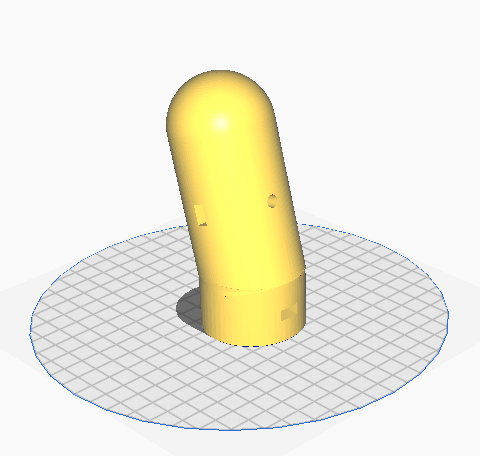

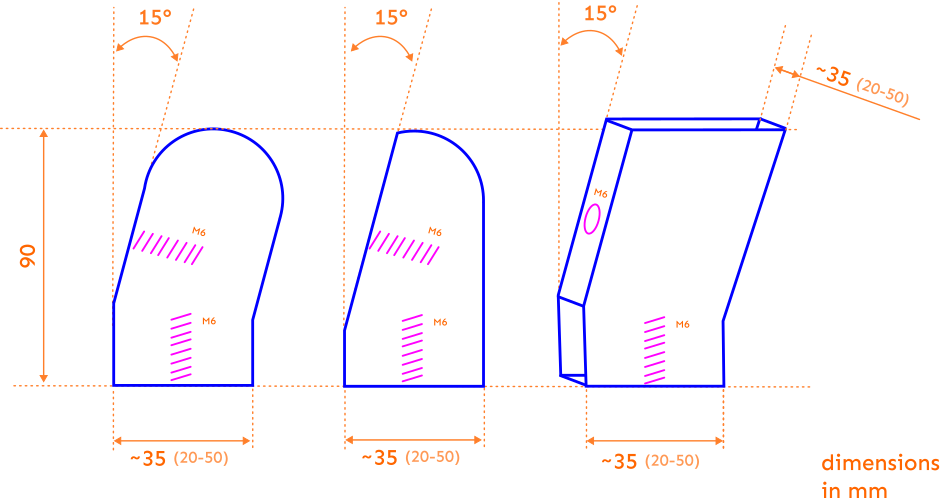

Bend 1 – 120mm, 15°, 1 hole

Download .stl file to 3D print

Basic Info

- What is it: a rod with a 15° bend and two M6 insert threads

- Material: strong | standard tolerance (more infos in the “Make” section below)

- Dimensions: 120mm high (fixed), diameter ~35mm, more infos in the drawing and in the “Make” section below | standard tolerance

- Holes: 2 insert M6 threads, see drawing for locations

Get the part

- Buy: Available as local make.

- Make + General info:

-

- The aim of the part is to have a 15° deflection for the Elephant Rods (Ikego parts 095.1-095.5), which also allows elements to be bolted onto the slanted side.

- Therefore, there must be a possibility to screw in an M6 bolt at the bottom and on the side. How this is technically realised depends on the material and manufacturing technique used to produce the part (see material tolerance and the info below)

- The left-hand side of the sketch and the actual photo of the component show the upper end rounded. But this does not have to be the case (see dimensions tolerance). Square ends at the top are also possible. The whole component does not have to be round at all. It can also simply be a wooden angle cut out of a thicker piece, which is shown in the drawing.

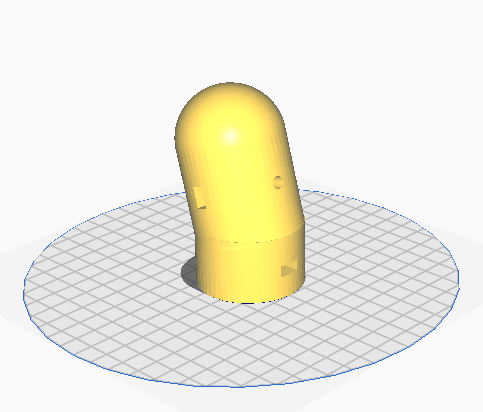

- We provide an STL for one version for 3D-printing. The print version we provide fully utilises the dimension tolerance of Ikego; the part in our STL file has a diameter of 50 mm. The screw-in thread in our 3D printed component is produced using a regular DIN M6 hexagon nut, which is simply pushed into the component from the side and then covered with a lock if you like. Detailed instructions after the STL download.

- In addition to 3D printing, we see the following option for manufacturing the part:

- You can simply saw it out square from thicker material and then add regular insert nuts.

- You can take a piece of wooden beam or a thick round bar made of wood and simply remove the 15° angle with a grinding disc. Then simply work in regular screw-in nuts.

- Injection moulding can also work. You create a solid piece of plastic in the right shape then simply cut in the threads – either with a tap or by inserting a screw-in nut.

- Pipes can be sawn at the appropriate angle and welded or glued together again and then the threads can be inserted, e.g. at the bottom using inserts (see Elephant Rods – Ikego parts 095.1-095.5) and at the edge using a tap.

- What other manufacturing options do you see?

Meta

- Introduced by: Lars Zimmermann

- Open: Shared under IPP 1.0

- Disclaimer: This part is just a concept and not fully tested. You should not assume that it works as indicated and I am not saying that it does. I disclaim any responsibility or liability for any damage caused during the construction and use of products based in whole or in part on the concept shown here. All information is provided for your use at your own risk.

2

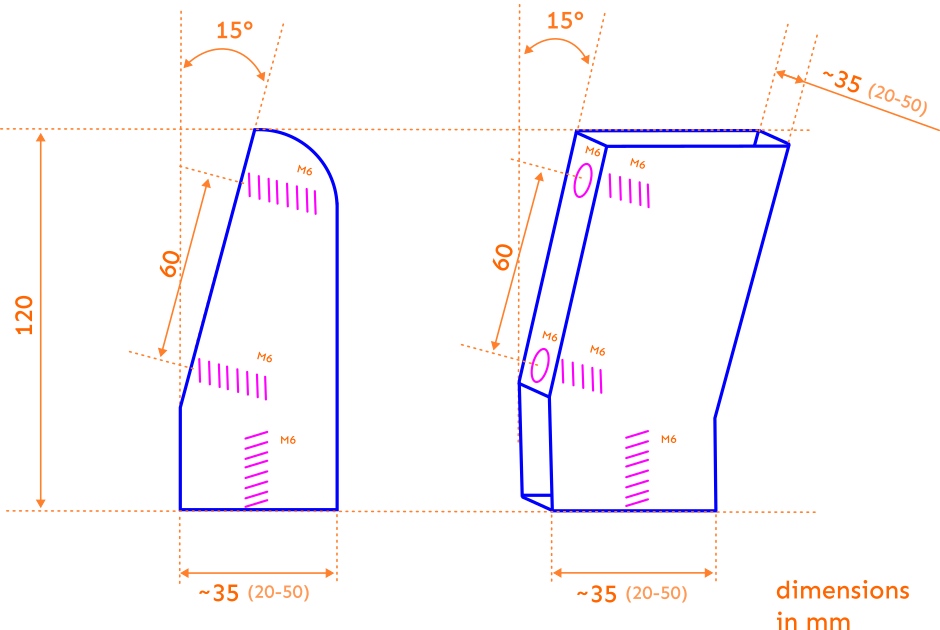

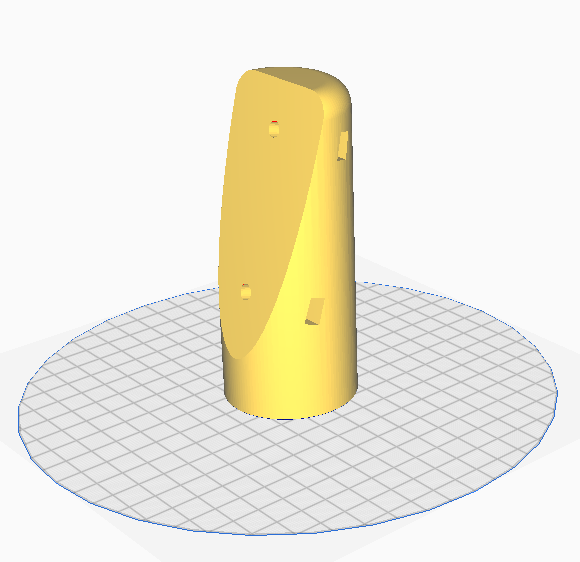

Bend 1, vs2 – 120mm, 15°, 2 hole

Download .stl file to 3D print

Basic Info

- What is it: a rod with a 15° bend and three M6 insert threads

- Material: strong | standard tolerance (more infos in the “Make” section below)

- Dimensions: 120mm high (fixed), diameter ~35mm, more infos in the drawing and in the “Make” section below | standard tolerance

- Holes: 3 insert M6 threads, see drawing for locations

Get the part

- Buy: Available as local make.

- Make + General info:

-

- The aim of the part is to have a 15° deflection for the Elephant Rods (Ikego parts 095.1-095.5), which also allows elements to be bolted onto the slanted side.

- Therefore, there must be a possibility to screw in an M6 bolt at the bottom and on the side. How this is technically realised depends on the material and manufacturing technique used to produce the part (see material tolerance and the info below)

- The left-hand side of the sketch and the actual photo of the component show the upper end rounded. But this does not have to be the case (see dimensions tolerance). Square ends at the top are also possible. The whole component does not have to be round at all. It can also simply be a wooden angle cut out of a thicker piece, which is shown in the drawing.

- We provide an STL for one version for 3D-printing. The print version we provide fully utilises the dimension tolerance of Ikego; the part in our STL file has a diameter of 50 mm. The screw-in thread in our 3D printed component is produced using a regular DIN M6 hexagon nut, which is simply pushed into the component from the side and then covered with a lock if you like. Detailed instructions after the STL download.

- In addition to 3D printing, we see the following option for manufacturing the part:

- You can simply saw it out square from thicker material and then add regular insert nuts.

- You can take a piece of wooden beam or a thick round bar made of wood and simply remove the 15° angle with a grinding disc. Then simply work in regular screw-in nuts.

- Injection moulding can also work. You create a solid piece of plastic in the right shape then simply cut in the threads – either with a tap or by inserting a screw-in nut.

- Pipes can be sawn at the appropriate angle and welded or glued together again and then the threads can be inserted, e.g. at the bottom using inserts (see Elephant Rods – Ikego parts 095.1-095.5) and at the edge using a tap.

- What other manufacturing options do you see?

Meta

- Introduced by: Lars Zimmermann

- Open: Shared under IPP 1.0

- Disclaimer: This part is just a concept and not fully tested. You should not assume that it works as indicated and I am not saying that it does. I disclaim any responsibility or liability for any damage caused during the construction and use of products based in whole or in part on the concept shown here. All information is provided for your use at your own risk.

3

Bend 2 – 90mm, 15°

Download .stl file to 3D print

Basic Info

- What is it: a rod with a 15° bend and two M6 insert threads

- Material: strong | standard tolerance (more infos in the “Make” section below)

- Dimensions: 90mm high (fixed), diameter ~35mm, more infos in the drawing and in the “Make” section below | standard tolerance

- Holes: 2 insert M6 threads, see drawing for locations

Get the part

- Buy: Available as local make.

- Make + General info:

-

- The aim of the part is to have a 15° deflection for the Elephant Rods (Ikego parts 095.1-095.5), which also allows elements to be bolted onto the slanted side.

- Therefore, there must be a possibility to screw in an M6 bolt at the bottom and on the side. How this is technically realised depends on the material and manufacturing technique used to produce the part (see material tolerance and the info below)

- The left-hand side of the sketch and the actual photo of the component show the upper end rounded. But this does not have to be the case (see dimensions tolerance). Square ends at the top are also possible. The whole component does not have to be round at all. It can also simply be a wooden angle cut out of a thicker piece, which is shown in the drawing.

- We provide an STL for one version for 3D-printing. The print version we provide fully utilises the dimension tolerance of Ikego; the part in our STL file has a diameter of 50 mm. The screw-in thread in our 3D printed component is produced using a regular DIN M6 hexagon nut, which is simply pushed into the component from the side and then covered with a lock if you like. Detailed instructions after the STL download.

- In addition to 3D printing, we see the following option for manufacturing the part:

- You can simply saw it out square from thicker material and then add regular insert nuts.

- You can take a piece of wooden beam or a thick round bar made of wood and simply remove the 15° angle with a grinding disc. Then simply work in regular screw-in nuts.

- Injection moulding can also work. You create a solid piece of plastic in the right shape then simply cut in the threads – either with a tap or by inserting a screw-in nut.

- Pipes can be sawn at the appropriate angle and welded or glued together again and then the threads can be inserted, e.g. at the bottom using inserts (see Elephant Rods – Ikego parts 095.1-095.5) and at the edge using a tap.

- What other manufacturing options do you see?

Meta

- Introduced by: Lars Zimmermann

- Open: Shared under IPP 1.0

- Disclaimer: This part is just a concept and not fully tested. You should not assume that it works as indicated and I am not saying that it does. I disclaim any responsibility or liability for any damage caused during the construction and use of products based in whole or in part on the concept shown here. All information is provided for your use at your own risk.

4

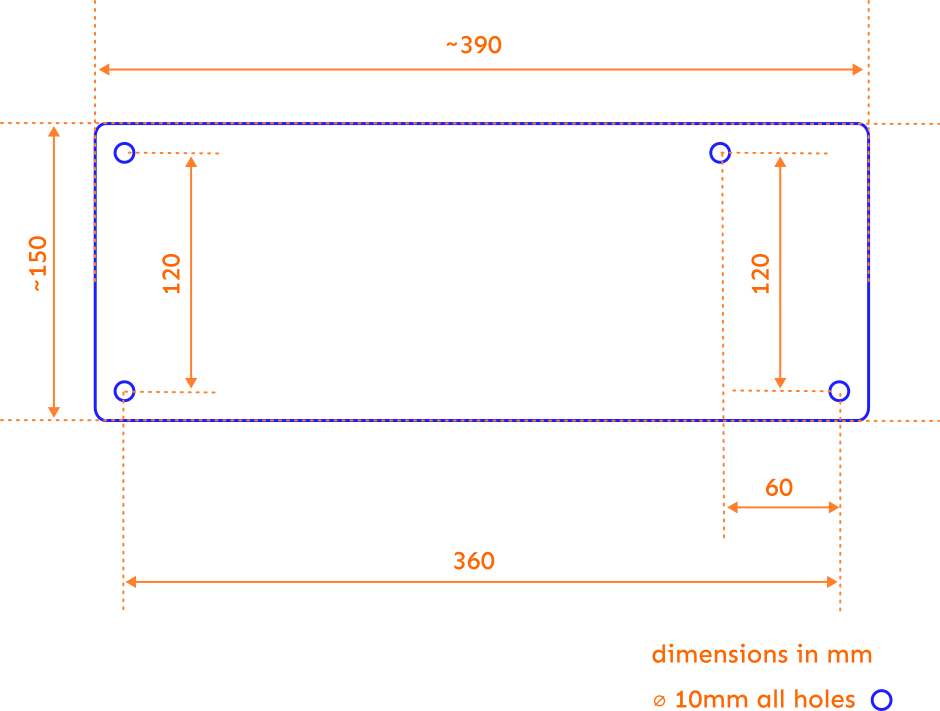

Board

Basic Info

- What is it: a board

- Material: strong | standard tolerance

- Dimensions: ~360x150x16mm| standard tolerance

- Holes: Ikego Grid, 4 holes ⌀ 10mm, see drawing for location

Get the part

- Buy: available as local make

- Make: no instructions available

Meta

- Introduced by: Lars Zimmermann

- Open: Shared under IPP 1.0

- Disclaimer: This part is just a concept and not fully tested. You should not assume that it works as indicated and I am not saying that it does. I disclaim any responsibility or liability for any damage caused during the construction and use of products based in whole or in part on the concept shown here. All information is provided for your use at your own risk.

Spacer 60mm high, ⌀ ~35mm

Basic Info

- What is it: a spacer

- Material: strong| standard tolerance

- Dimensions: 60mm high (fixed), diameter ~35 mm and flexible within the | standard tolerance

- Holes: 1 hole ⌀ 10mm, location see picture

Get the part

- Buy: available as local make

- Make: no instructions available

Meta

- Introduced by: Lars Zimmermann

- Open: Shared under IPP 1.0

- Disclaimer: This part is just a concept and not fully tested. You should not assume that it works as indicated and I am not saying that it does. I disclaim any responsibility or liability for any damage caused during the construction and use of products based in whole or in part on the concept shown here. All information is provided for your use at your own risk.

DISCLAIMER

These parts and objects is just a concept and not fully tested. You should not assume that it works as indicated and I am not saying that it does. I disclaim any responsibility or liability for any damage caused during the construction and use of products based in whole or in part on the concept shown here. All information is provided for your use at your own risk.

LICENSE

This post is NOT shared under the CC-BY license but fully copyrighted